The 4L60E manual shift wiring diagram is essential for installing and troubleshooting manual shifting in GM’s popular automatic transmission, enabling precise control over gear changes and diagnostics.

1.1 Overview of the 4L60E Transmission

The 4L60E is a widely used automatic transmission developed by General Motors (GM), designed for rear-wheel-drive vehicles. It is an electronically controlled, four-speed automatic transmission known for its durability and versatility. First introduced in the early 1990s, the 4L60E quickly became a staple in GM’s lineup, powering iconic vehicles like the Chevrolet Silverado, GMC Sierra, and various performance cars. One of its standout features is its ability to adapt to manual shifting through aftermarket modifications, making it a popular choice for enthusiasts seeking more control over gear changes. The transmission’s compact design, combined with its robust construction, allows it to handle a wide range of engine torque outputs, from everyday commuter vehicles to high-performance applications. Its electronic control system also enables precise shifting and adaptive learning, which enhances overall driving efficiency and responsiveness.

1.2 Importance of Manual Shifting in Modern Transmissions

Manual shifting in modern transmissions, such as the 4L60E, offers enhanced driver control and precision, particularly in high-performance or towing scenarios. While automatic transmissions are convenient, manual shifting allows drivers to override automatic gear changes, ensuring optimal power delivery and efficiency. This feature is especially valuable in situations requiring precise control, such as racing, mountain driving, or hauling heavy loads. Modern transmissions integrate electronic controls to facilitate manual shifting seamlessly, eliminating the need for a traditional clutch pedal. By enabling drivers to select gears manually, the 4L60E can deliver improved acceleration, reduced wear on the transmission, and a more engaging driving experience. This capability bridges the gap between automatic convenience and manual performance, making it a desirable upgrade for enthusiasts seeking greater control over their vehicle’s behavior.

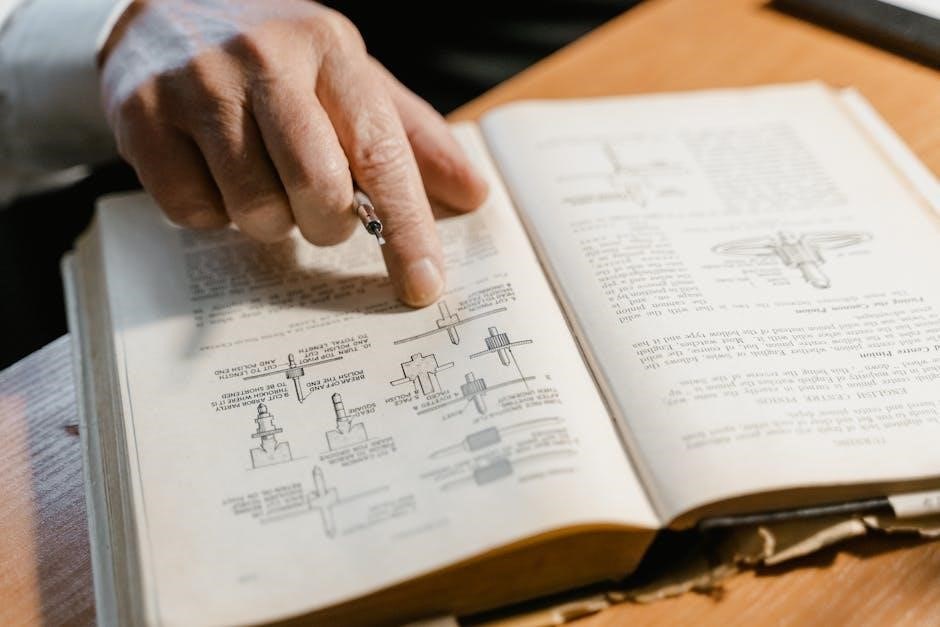

1.3 Purpose of the Wiring Diagram

The wiring diagram for the 4L60E manual shift conversion serves as a comprehensive guide to understanding and installing the necessary electrical components. It provides a detailed visual representation of the wiring connections, solenoids, sensors, and control modules involved in the manual shifting system. This diagram is essential for ensuring proper installation, troubleshooting, and maintenance of the transmission. By following the wiring diagram, technicians and enthusiasts can identify each wire’s function, connection points, and how they integrate with the vehicle’s electrical system. This ensures that the manual shift functionality operates smoothly and safely. The diagram also acts as a reference for diagnosing electrical issues and performing upgrades or modifications to the transmission system. Its clarity and accuracy are critical for achieving reliable performance and preventing potential damage to the transmission or vehicle electronics.

Key Components of the 4L60E Manual Shift Wiring Diagram

The 4L60E manual shift wiring diagram consists of key components like the wiring harness, solenoid pack, Transmission Control System (TCS), and manual shift linkage for precise control.

2.1 Understanding the Wiring Harness

The wiring harness is the backbone of the 4L60E manual shift wiring diagram, connecting electrical components like solenoids, sensors, and the Transmission Control System (TCS). It consists of durable wires, connectors, and insulation, ensuring reliable signal transmission. The harness is pre-configured for specific transmission functions, including gear actuation and torque converter control. Proper routing and securing of the harness are essential to prevent damage from heat, vibrations, or abrasion. Incorrect wiring can lead to malfunctions, so careful installation is critical. The harness also integrates with the vehicle’s ECU, enabling seamless communication for manual shifting operations. Regular inspection and testing of the wiring harness are recommended to ensure optimal performance and prevent potential issues during manual shifting. This component is vital for maintaining precise control over the transmission’s operations.

2.2 Role of the Solenoid Pack in Manual Shifting

The solenoid pack plays a pivotal role in the 4L60E manual shift wiring diagram, serving as the electrical interface for transmission control. It comprises multiple solenoids that regulate fluid pressure within the transmission, enabling precise gear actuation during manual shifting. These solenoids are controlled by electrical signals from the Transmission Control System (TCS) or manual shift controls, ensuring smooth and accurate gear transitions. The solenoid pack is responsible for activating components like the torque converter clutch (TCC) and shift solenoids, which directly influence the transmission’s shifting behavior. Proper wiring and activation of the solenoid pack are critical to avoid issues like erratic shifting or loss of manual control. By integrating with the wiring harness and TCS, the solenoid pack ensures that manual shifting commands are executed efficiently and reliably. This component is essential for maintaining precise control over the transmission’s operational parameters during manual shifting.

2.3 Function of the Transmission Control System (TCS)

The Transmission Control System (TCS) is a critical component in the 4L60E manual shift wiring diagram, responsible for managing gear shifts based on driver input and vehicle conditions. It interprets signals from sensors, such as throttle position, vehicle speed, and engine RPM, to determine the optimal gear for smooth operation. In manual shifting mode, the TCS interfaces with the driver’s commands, either through a shifter or manual shift buttons, to override automatic shifting. The system ensures that gear changes occur seamlessly, preventing abrupt shifts that could compromise performance or control. The TCS also communicates with the solenoid pack to activate the appropriate solenoids for desired gear engagement. While allowing driver control, the TCS maintains oversight to prevent operational extremes, ensuring the transmission operates within safe and efficient parameters. This balance of manual control and automated oversight enhances driving experience and transmission longevity.

2.4 Manual Shift Mechanism and Linkage

The manual shift mechanism and linkage in the 4L60E transmission are designed to provide precise control over gear shifts when operating in manual mode. The mechanism typically includes a gear shifter, linkage rods, and levers that connect to the transmission. These components work together to translate the driver’s input into mechanical movements, engaging the desired gear. The linkage ensures smooth communication between the shifter and the transmission, allowing for accurate gear selection. Proper alignment and adjustment of the linkage are critical to avoid issues like missed shifts or difficulty engaging gears. The manual shift mechanism also includes a detent mechanism to ensure the shifter stays in the selected gear position. This system is essential for drivers who prefer manual control over automatic shifting, offering a more engaging and responsive driving experience. Regular maintenance of the linkage and mechanism is vital to maintain reliable operation.

Installation and Setup of the Manual Shift Wiring

The installation involves connecting the wiring harness to the transmission, configuring solenoids, and routing cables safely. Proper setup ensures smooth manual shifting functionality and reliable performance.

3.1 Preparing the Vehicle for Manual Shift Conversion

Preparing the vehicle for a manual shift conversion involves several critical steps. Start by disconnecting the battery to prevent electrical shocks or system activation. Drain the transmission fluid and remove the pan to access the valve body. Cover the interior and surrounding components to protect them from fluid spills. Next, purchase and assemble the manual shift kit, ensuring all components are included. Install the transmission control switch (TCS) on the gear selector, following the manufacturer’s instructions. Finally, attach the manual shift linkage to the transmission, aligning it properly with the gear selector. Double-check all connections before proceeding to ensure a smooth installation process.

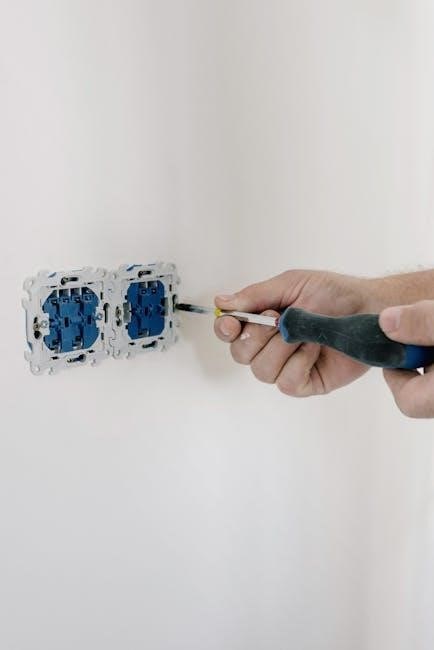

3.2 Connecting the Wiring Harness to the Transmission

Connecting the wiring harness to the transmission is a critical step in the manual shift conversion. Begin by locating the transmission’s electrical connectors, typically found near the valve body or solenoid pack; Align the wiring harness connectors with the transmission’s ports, ensuring they match in both shape and function. Securely attach the connectors, making sure they are fully seated to avoid poor connections. Next, connect the transmission control system (TCS) and solenoid wires to their respective terminals. Use zip ties or heat-resistant tape to route the harness away from moving components. Finally, verify all connections by gently tugging on the wires to ensure they are secure. Proper installation ensures reliable communication between the transmission and the manual shift system.

3.3 Configuring the Solenoid and TSS Cables

Configuring the solenoid and TSS (Throttle Position Sensor) cables is essential for proper manual shift operation. Begin by identifying the solenoid pack, which controls gear shifts, and the TSS, which regulates torque converter engagement. Locate the designated ports on the transmission for these cables and ensure they are free from damage or corrosion. Connect the solenoid wires to the appropriate terminals, following the wiring diagram to match the correct pin assignments. For the TSS, attach the cable to the throttle pedal assembly, ensuring proper alignment and tension. Use electrical connectors or soldering to secure the connections, then wrap the cables with heat-resistant sleeving for protection. Finally, test the system by manually shifting through gears and monitoring the transmission’s response to ensure smooth engagement and disengagement.

3.4 Routing the Wiring Harness Safely

Properly routing the wiring harness is critical to ensure reliability and prevent damage. Begin by securing the harness to the vehicle’s frame or existing wiring looms using zip ties or adhesive-backed clips. Avoid routing wires near moving components, such as the driveshaft or suspension, as this could cause wear or damage. Keep the harness away from high-temperature areas, such as the exhaust system or engine block, to prevent heat damage. Use protective sleeves or heat shrink tubing on sections exposed to heat. Ensure all connections are secure and grounded properly to avoid electrical interference. Regularly inspect the harness for signs of wear or damage, and repair or replace it as needed. This careful routing ensures long-term functionality and safety of the manual shift system.

3.5 Testing the Manual Shift Functionality

After completing the wiring setup, thoroughly test the manual shift functionality to ensure proper operation. Start by turning the ignition to the “on” position and checking for any dashboard warning lights related to the transmission. Use a scan tool to monitor solenoid activation and verify that each gear engages smoothly. Perform a test drive in a controlled environment, manually shifting through all gears to confirm proper engagement and no slipping. Pay attention to the transmission’s response time and ensure there are no sudden or unexpected shifts. If any issues arise, such as delayed or missed shifts, refer to the wiring diagram to trace and repair any electrical faults. Testing under varying conditions, including low and high throttle inputs, will help identify any inconsistencies. This step ensures the manual shift system operates reliably and as intended.

Troubleshooting Common Issues

Troubleshooting the 4L60E manual shift wiring involves checking connections, testing solenoids, verifying TCS configuration, inspecting the shift mechanism, ensuring proper harness routing, checking sensors, and addressing TCM issues. Start with basics and progress systematically.

4.1 Diagnosing Gear Shifting Problems

Diagnosing gear shifting issues in a 4L60E manual shift setup involves identifying symptoms like erratic shifts, slipping, or failure to engage gears. Start by checking the throttle position sensor (TPS) and vehicle speed sensor (VSS) for accurate readings. Verify the transmission control system (TCS) is properly configured and receiving correct input signals. Inspect the solenoid pack for malfunctioning solenoids, as this can disrupt gear changes. Ensure the wiring harness is free from damage or corrosion, and all connections are secure. Use a scan tool to monitor transmission control module (TCM) error codes, which can pinpoint specific issues. Testing individual components like the torque converter clutch (TCC) solenoid or pressure control solenoid can isolate the problem. Referencing the wiring diagram is essential to trace circuits and verify proper operation. Systematic troubleshooting ensures accurate diagnosis and effective repairs. Always consult the diagram to avoid misdiagnosis.

4.2 Identifying and Repairing Electrical Connectivity Issues

Electrical connectivity issues in the 4L60E manual shift wiring diagram can cause erratic or failed gear shifts. Begin by inspecting all connectors and terminals for corrosion, damage, or loose connections. Use a multimeter to test for continuity and voltage drops across critical circuits, such as the solenoid pack and transmission control system (TCS). Check the wiring harness for chafing or pinched wires, which can disrupt signal flow. If a fault is found, repair or replace the affected wires or connectors. Ensure all ground points are clean and securely fastened, as poor grounding is a common cause of electrical malfunctions. Apply dielectric grease to connectors to prevent corrosion and ensure reliable connections. Properly routing and securing the wiring harness during installation can prevent future issues. Always refer to the wiring diagram to trace circuits accurately and confirm proper connectivity.

4.3 Solving Solenoid Malfunction Symptoms

Solenoid malfunctions in the 4L60E manual shift wiring diagram can lead to erratic gear shifts, slipping, or failure to engage gears. Start by checking the solenoid pack for electrical issues. Use a multimeter to verify proper voltage supply and continuity. Inspect the wiring harness for any damage or corrosion that could disrupt the signal to the solenoids. If a solenoid is faulty, replace it with an OEM or high-quality aftermarket unit. Ensure the transmission control module (TCM) is functioning correctly, as it regulates solenoid operation. After repairs, test the transmission in manual shift mode to confirm smooth gear transitions. Properly bleeding the transmission and resetting the TCM may also be necessary. Addressing solenoid issues promptly prevents further damage to the transmission and ensures reliable performance.

4.4 Addressing TSS-Related Problems

TSS-related issues in the 4L60E manual shift wiring diagram often stem from faulty sensors or wiring connections. Begin by diagnosing the Transmission Speed Sensor (TSS) to ensure it accurately monitors gear changes. Use a multimeter to check for proper voltage and continuity in the TSS circuit. Inspect the wiring harness for any signs of damage or corrosion that could disrupt signals. If the TSS is malfunctioning, replace it with a compatible OEM or aftermarket sensor. Refer to the wiring diagram to verify all connections are correct and securely fastened. Additionally, check for any error codes using a scan tool, as they can pinpoint TSS-related faults. After repairs, test the transmission in manual shift mode to ensure smooth gear engagement and proper function. Addressing TSS issues promptly prevents further complications and maintains optimal transmission performance.

Advanced Modifications for Enhanced Performance

Advanced modifications for the 4L60E manual shift wiring diagram include upgrading to a custom wiring harness, integrating a stand-alone transmission controller, and modifying the valve body for enhanced performance and control.

5.1 Upgrading to a Custom Wiring Harness

Upgrading to a custom wiring harness for the 4L60E manual shift wiring diagram is a popular modification for enhanced performance and reliability. A custom harness is designed to streamline the electrical connections, reducing clutter and potential failures. It often includes high-quality materials, such as heat-resistant wires and durable connectors, ensuring long-term durability. This upgrade is particularly beneficial for high-performance applications, as it minimizes electrical interference and ensures consistent signal transmission to the solenoid pack and TCS. A custom harness can also be tailored to accommodate additional features, such as analog pressure adjustments or manual torque converter control. By eliminating factory limitations, a custom wiring harness provides a cleaner, more efficient setup for manual shifting, making it a key upgrade for enthusiasts seeking improved transmission performance.

5.2 Integrating a Stand-Alone Transmission Controller

Integrating a stand-alone transmission controller into the 4L60E manual shift wiring diagram offers enhanced control and flexibility for high-performance applications. This controller operates independently of the vehicle’s main ECU, allowing precise management of shift points, torque converter lockup, and line pressure. It is particularly beneficial for enthusiasts seeking customized transmission behavior, as it enables adjustability for various driving conditions. The stand-alone unit connects directly to the wiring harness, bypassing the factory ECU’s limitations. While installation requires expertise, the ability to fine-tune transmission performance makes it a valuable upgrade for racing or heavily modified vehicles. Proper setup ensures seamless communication between the controller and solenoid pack, delivering optimal shifting characteristics and improved drivetrain efficiency. This modification is ideal for those pursuing maximum control over their 4L60E transmission’s operation.

5.3 Modifying the Valve Body for Manual Shifting

Modifying the valve body is a critical step for achieving precise control in manual shifting with the 4L60E transmission. The valve body regulates fluid flow and shift timing, and customizing it allows for improved hydraulic pressure control and faster, more responsive shifts. Common modifications include upgrading the hydraulic circuits, installing manual shift valves, or adding a manual valve body kit. These changes enable direct driver input, bypassing the automatic shift logic. For high-performance applications, porting and polishing the valve body can further enhance fluid flow efficiency. However, such modifications require a deep understanding of transmission internals and hydraulic principles. Incorrect adjustments can lead to poor shift quality or transmission damage. Consulting an experienced technician or using specialized tools is highly recommended to ensure proper calibration and functionality.

Thank you for following this guide on the 4L60E manual shift wiring diagram. Proper setup and troubleshooting are key to achieving reliable performance and control. Always prioritize precision and safety.

6.1 Summary of Key Takeaways

- Understand the wiring harness and its role in manual shifting.

- Ensure proper solenoid and TCS configuration.

- Address common issues promptly to maintain performance.

6.2 Importance of Proper Wiring and Setup

Proper wiring and setup are critical for ensuring the 4L60E manual shift system operates efficiently and reliably. Incorrect or damaged wiring can lead to electrical faults, erratic gear shifting, and even complete system failure. A well-configured wiring harness ensures seamless communication between the transmission, solenoids, and control systems. Additionally, accurate setup of the solenoid pack and Transmission Control System (TCS) guarantees precise shifting and optimal performance. Improper connections or misconfigurations can result in safety hazards, such as unintended gear changes or loss of control. Always use high-quality materials and follow the wiring diagram meticulously to avoid issues. Regularly inspect and maintain the wiring to prevent degradation over time. Proper installation is the foundation of a reliable manual shift system.

- Ensure precise communication between components.

- Prevent electrical faults and system failures.

- Guarantee safety and optimal performance.

6.3 Future Considerations for Manual Shift Upgrades

As automotive technology evolves, future considerations for manual shift upgrades on the 4L60E transmission may involve integrating advanced electronic controls and adaptive shifting algorithms. Upgrading to a stand-alone transmission controller or incorporating modern engine management systems could enhance performance and customization. Additionally, advancements in wiring materials and connectors may improve durability and reliability. Future modifications might also focus on optimizing the manual shift mechanism for smoother engagement and reduced wear. Exploring compatibility with emerging technologies, such as hybrid or electric drivetrains, could further expand the capabilities of the 4L60E. Staying informed about industry trends and updates will help enthusiasts and technicians maximize the potential of their manual shift setups.

- Integrate advanced electronic controls for better performance.

- Adaptive shifting algorithms for enhanced driveability.

- Explore compatibility with emerging automotive technologies.

Additional Resources and References

Explore official GM manuals, online forums, and specialized tools for detailed guidance on 4L60E manual shift wiring. These resources provide comprehensive support for successful installations and troubleshooting.

- Official GM service manuals for accurate specifications.

- Specialized transmission tools for precise adjustments.

- Online forums for community-driven solutions and advice.

7.1 Recommended Tools and Materials

When working with the 4L60E manual shift wiring diagram, having the right tools and materials is essential for a successful project. Start with basic tools like wire strippers, crimpers, and a multimeter for diagnosing electrical issues. A set of Torx and hex keys will help with transmission disassembly. For wiring, high-quality 18-gauge wire, heat shrink tubing, and weatherproof connectors are recommended to ensure durability. A wiring harness repair kit can be invaluable for fixing damaged connections. Additionally, a transmission pan gasket set and fluid pump are necessary for any fluid changes or repairs. For advanced modifications, consider a custom wiring harness kit or a stand-alone transmission controller. Always use OEM or equivalent parts to maintain reliability and performance. Having these tools on hand will streamline the process and ensure a professional-grade installation.

7.2 Suggested Reading and Guides

For a deeper understanding of the 4L60E manual shift wiring diagram, several resources are highly recommended. Start with the official GM 4L60E service manual, which provides detailed specifications and procedures. DIY repair guides, such as those from Haynes or Chilton, offer step-by-step instructions tailored for enthusiasts. Technical bulletins from GM can shed light on common issues and solutions. Online forums like LS1Tech or Transmission Forums are invaluable for real-world troubleshooting and advice. Additionally, consider a comprehensive transmission repair manual for broader insights. A dedicated wiring diagram guide can help decipher complex circuits. For advanced projects, a transmission controller installation guide is essential. These resources collectively provide a robust foundation for successfully working with the 4L60E manual shift wiring diagram, ensuring both safety and optimal performance.

7.3 Online Communities and Forums for Support

Engaging with online communities and forums is crucial for troubleshooting and optimizing the 4L60E manual shift wiring diagram. Platforms like LS1Tech and CorvetteForum host extensive discussions on transmission modifications and wiring setups. Specialized forums such as Transmission Forums delve into gear-specific challenges and solutions. Facebook groups dedicated to automotive enthusiasts often share valuable insights and real-world experiences. Reddit communities like r/TransmissionRepair and r/CarMods provide accessible advice from experienced technicians and hobbyists. These platforms are excellent for asking questions, sharing progress, and gaining tips from those who have successfully implemented manual shift upgrades. Actively participating in these forums can significantly enhance your understanding and problem-solving skills when working with the 4L60E wiring diagram.